Professional Edging Products

Enhance your landscape projects with our premium selection of professional metal edging products. Designed to withstand the toughest challenges, our range of edging solutions ensures a seamless and long-lasting finish for every project.

Homeowner Edging Products

Transform your outdoor living spaces with our collection of high-quality metal edging products. Perfect for DIY enthusiasts and homeowners, our edging solutions add a touch of elegance to lawns, pathways, driveways and more.

Featured applications

View all applications

Metal Garden Edging

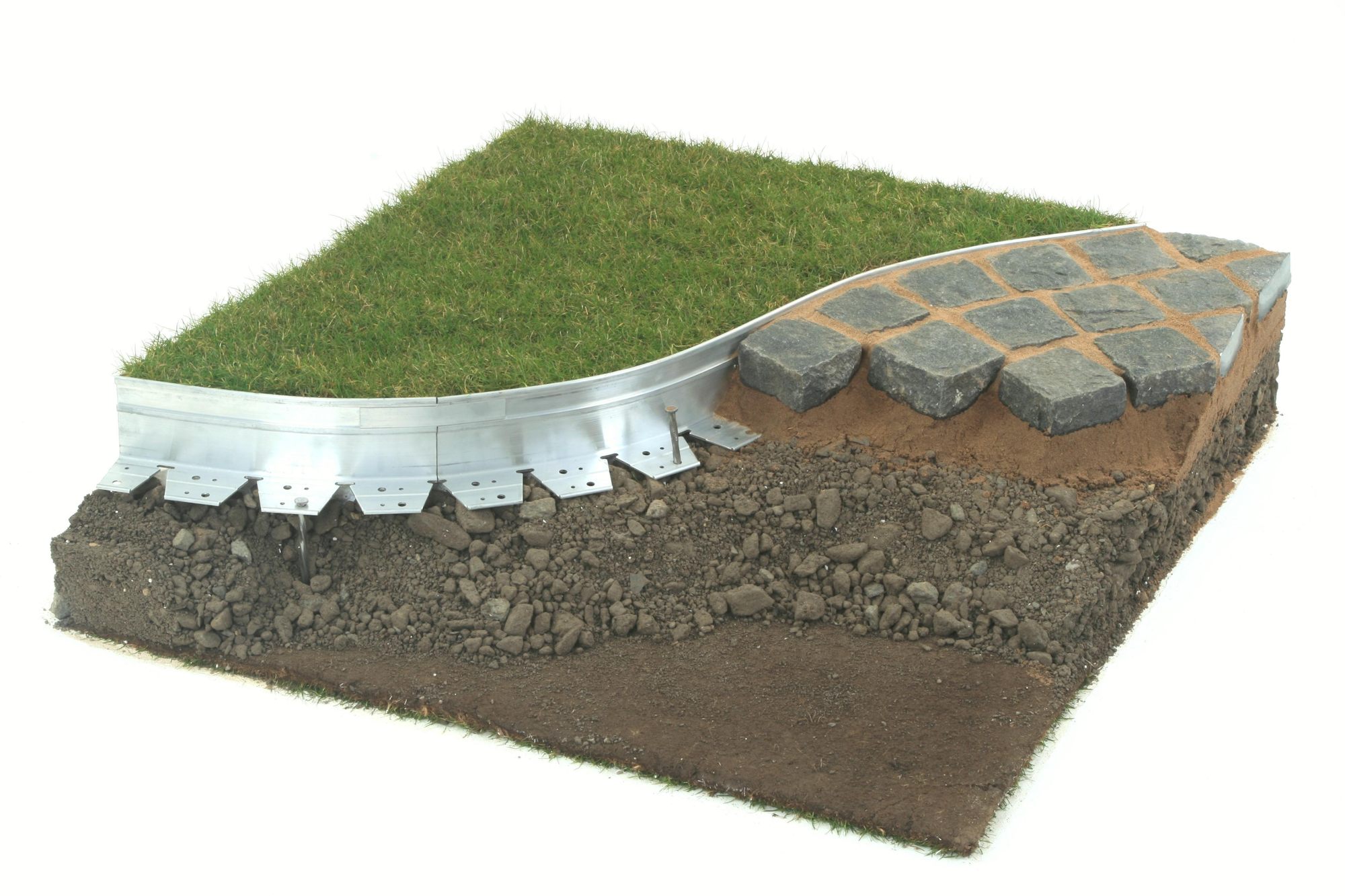

Metal Garden edging can help reduce the amount of maintenance needed by preventing lawns from invading flowerbeds or paths and mulch, gravel and other loose landscaping products from spreading onto adjoining areas.

Discover metal garden edging

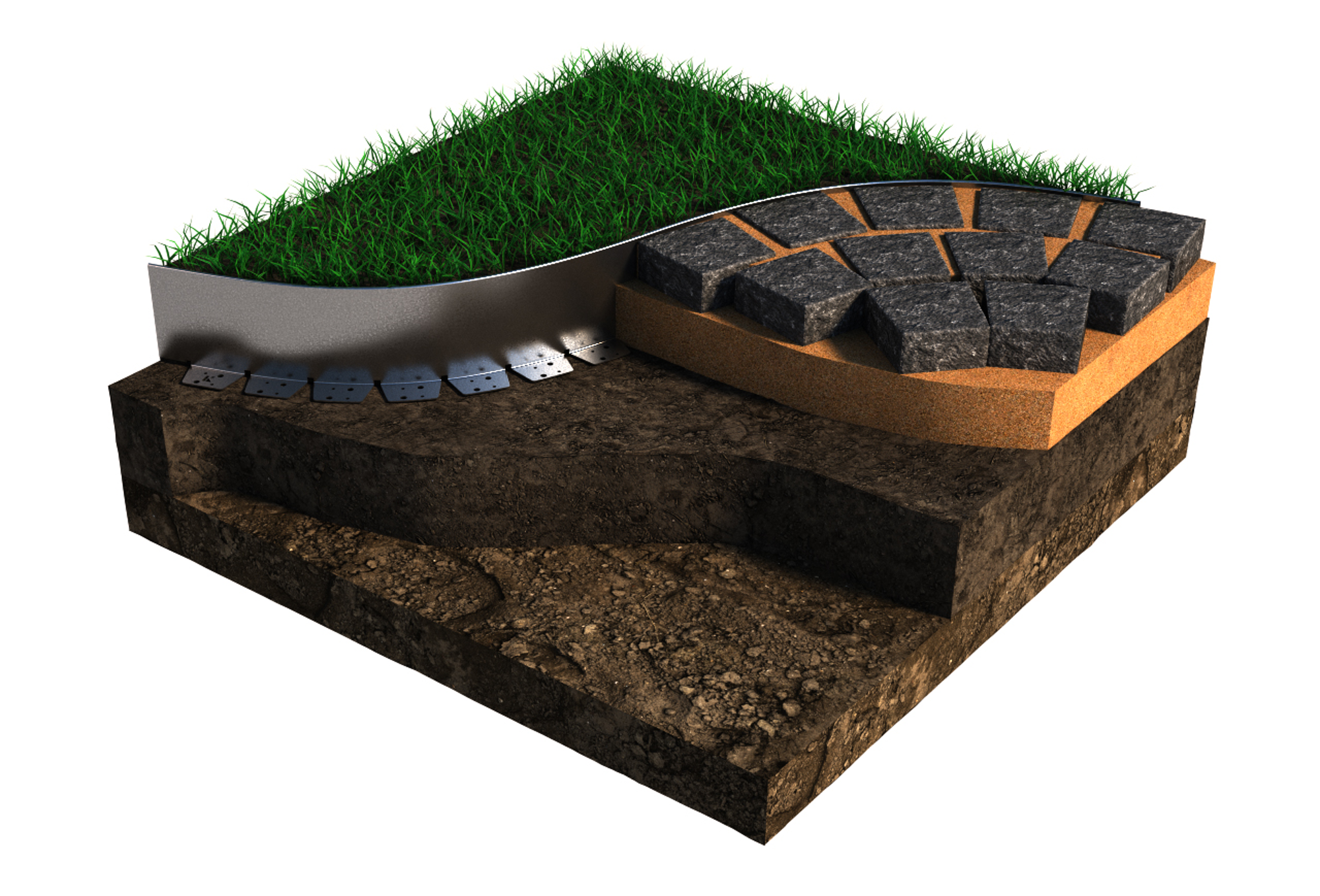

Footpaths

Footpaths, walkways and recreational areas have traditionally been bordered with concrete pin kerbing or timber edging. Metal landscape edging now offers an alternative with many benefits.

Discover footpath products

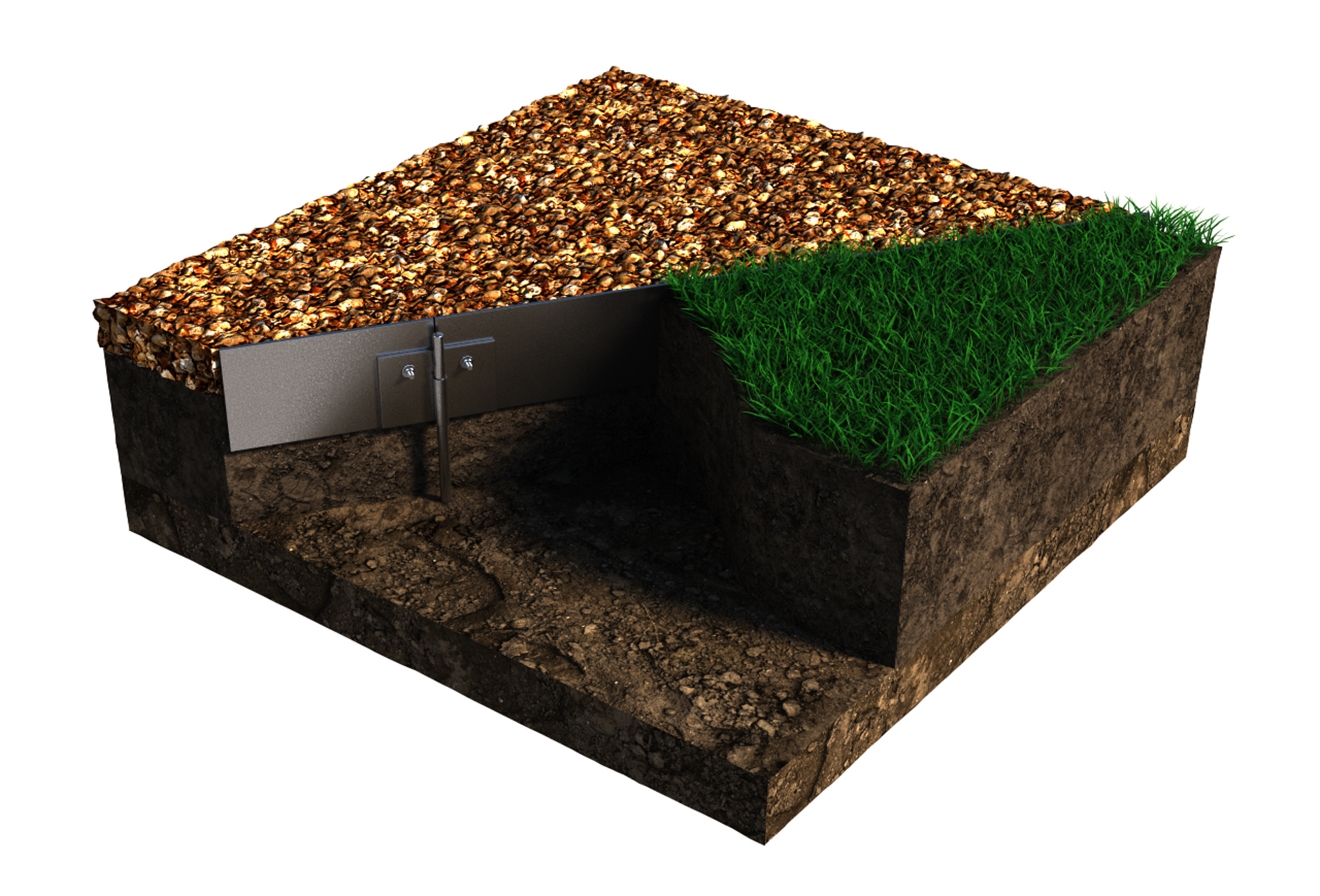

Driveways

Metal driveway edging products from ExcelEdge offer durable, low-maintenance alternatives that help preserve a driveway’s performance and appearance.

Discover driveway products

Play Areas

Play areas in parks, kindergarten and school playgrounds and other public and privately owned amenities are increasingly turning to wet-pour rubber crumb surfacing as a safe and environmentally-friendly ground coating for the areas around swings, slides and other play equipment.

Discover play area products

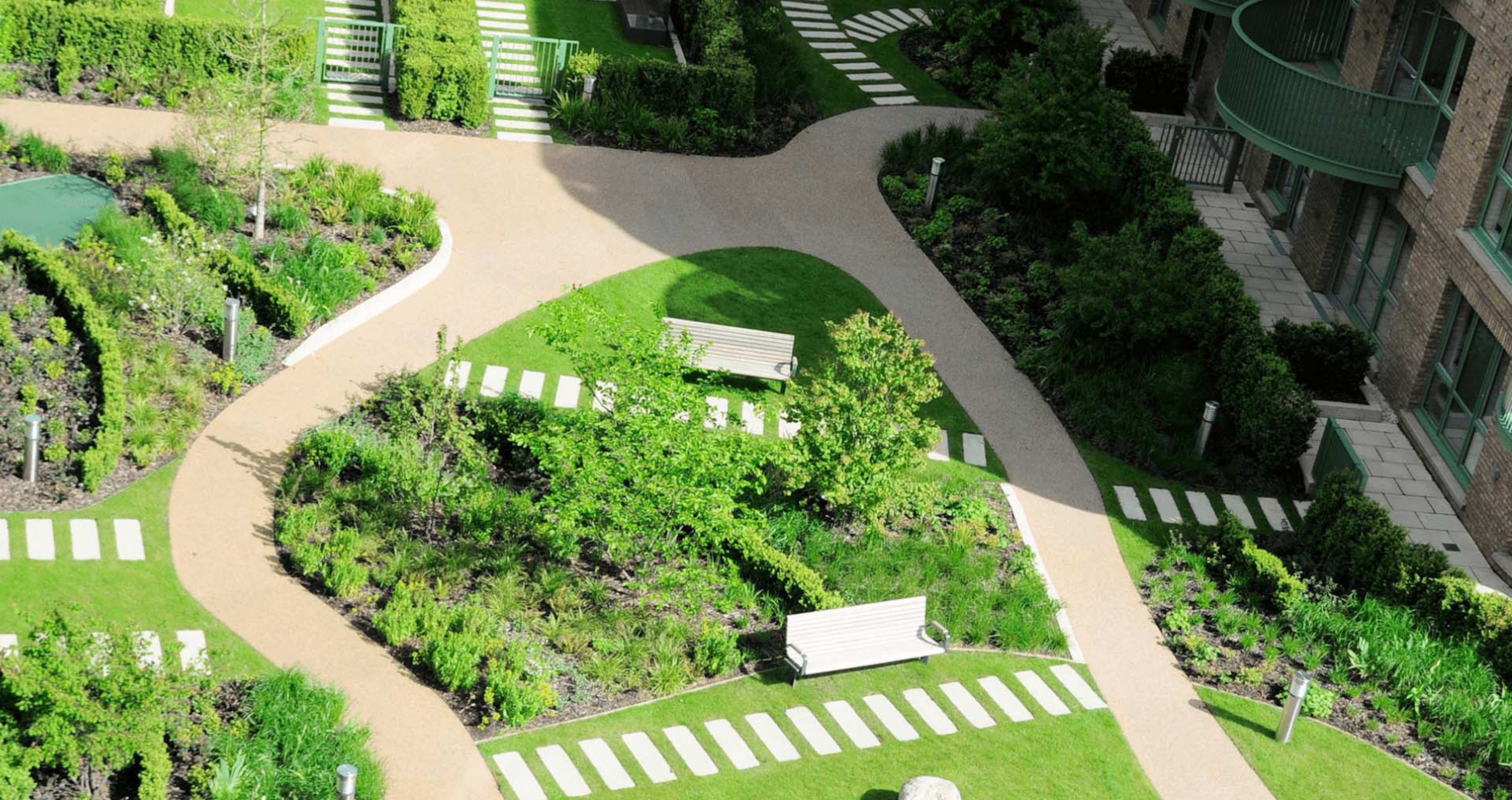

Courtyards

Concrete pin kerbing may be the traditional edging material for tarmac road surfaces but metal edging systems offer alternatives that are more versatile, faster to install, easier to handle, more durable and more cost-effective.

Discover car park products

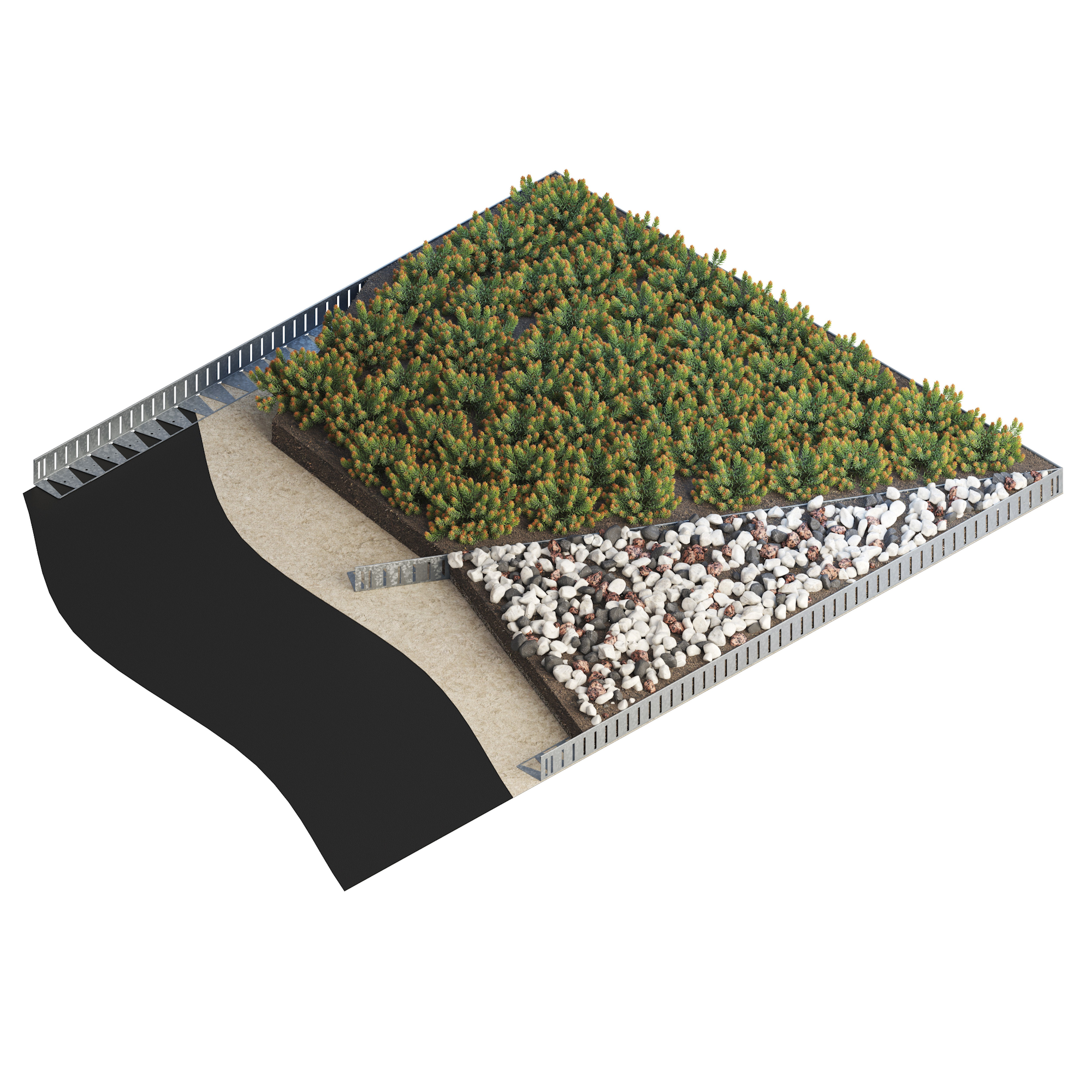

Roof Gardens

With the progressive movement towards ‘greening’ our city landscapes, architects, property developers and landlords are recognising the value of roof gardens and terraces when renovating or developing new commercial and residential property.

Discover roof garden products

What do our

customers think?

Kinley has significantly contributed to realising the vision for the project, with its products in use at multiple locations across the site. The flexibility in the aluminium allowed the design team to design more aesthetically pleasing layouts which were easily adhered to on the ground by the contractor.

From the very first contact I found Kinley to be extremely helpful and efficient.

The main reason for using the edging was to stop the grass edges from dying back. The AluExcel Edging forms nice neat curves and no brown grass also creating a defined edge between the resin bound gravel and the grassed areas.

Our team recognises the importance of engaging with leading suppliers and specialists on every aspect of the project. Kinley offered expert knowledge during the early stages of the project all the way through to site completion. As a result of this collaborative effort, the reaction from the client and wider team has been overwhelmingly positive.

The end result has justified all of our initial optimism that your Bison Edging was the right material for the job! All of the operatives we have put on the task have found the installation process extremely easy to pick up… Bison Edging is so much simpler to install than any other material currently in use! They have never layed material to a more precisely installed finished edge system!”

The Bison Kerb has improved our work in so many different ways. We’re not dealing with breaking concrete edgings, they’re really strong, sturdy, it’s just a much easier job in general…a lot faster. We thought they were going to be flimsy, but we tested them and you can drive on them, roll up right next to them and they don’t move at all. A perfect join between tarmac and grass! I would recommend using this over concrete. We’ve saved so much time with laying them, and with the tarmacking side as well. Great product!

Landscape Edging

The most comprehensive range of metal garden edging solutions that enable creativity, are fast to install and last for decades.

Kinley is the ideal solution for defining landscape and garden spaces. With great strength and durability, our metal garden edging ensures low maintenance and cost benefits across its long life-span. Kinley is renowned for its discreet and smart design, as well as simple installation. Aluminium and steel has become the first choice in landscape edging. Its strength, flexibility, durability and lightness contribute to simple, easy installation and minimal maintenance. With easy manual formation of curves and gradients the time consuming base preparation associated with traditional edging is eliminated.

About us

The Kinley team is a little bit obsessed with delivering quality products, going that extra mile for customers and making every process make sense. It’s this obsession that gives our Kinley customers the confidence in the longevity of the products, the reassurance of a stable, UK company and the expectation of that little bit extra when it comes to sales and installation support.

Let’s get started with making your garden beautiful.